-

Products

Overview Products

-

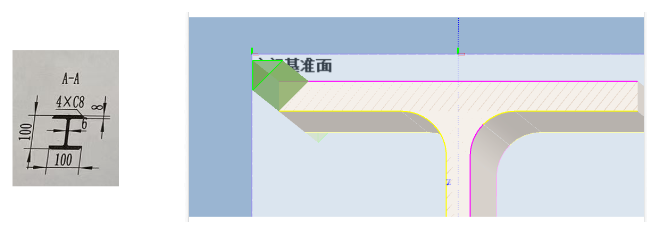

2D Cutting

-

Tube Cutting

-

3D Cutting

-

Intelligent Welding

-

Intelligent Cutting Head

-

Industrial Automation

-

Industrial Software

-

Combination

-

Combination

BOCHU New Product -

Combination

BOCHU New Product -

Controller

BOCHU New Product -

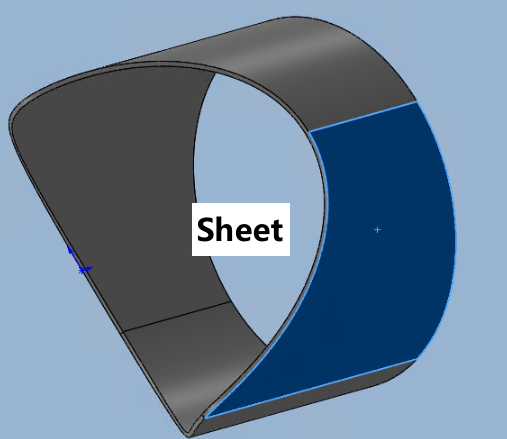

2D Cutting Head

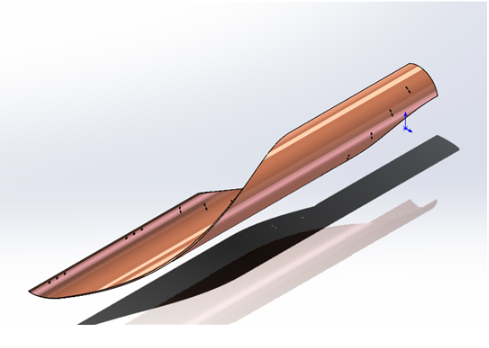

Tube Cutting Head

3D Cutting Head

Consumables

BOCHU New Product -

Servo

BOCHU New Product -

Industrial 4.0

-

- Support

- About

- Online Store

-英文.png)

- Software Download

- Manual

- Video

- Tutorial

品列表圖片_514x337.png)

品頁規(guī)格型號(hào).png)

品列表.png)