-

Products

Overview Products

-

2D Cutting

-

Tube Cutting

-

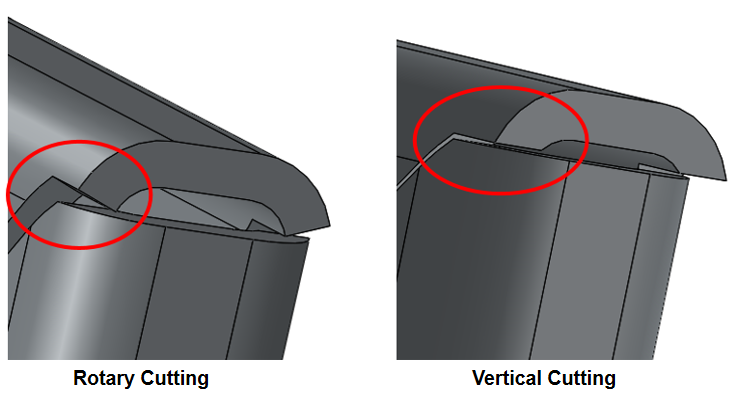

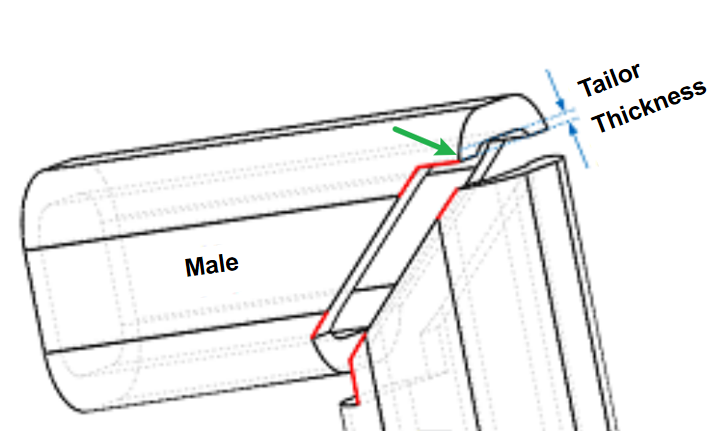

3D Cutting

-

Intelligent Welding

-

Intelligent Cutting Head

-

Industrial Automation

-

Industrial Software

-

Combination

Controller

-

Combination

BOCHU New Product -

Combination

BOCHU New Product -

Controller

BOCHU New Product -

2D Cutting Head

Tube Cutting Head

3D Cutting Head

BOCHU New Product -

BOCHU New Product

-

- Support

- About

- Online Store

- Software Download

- Manual

- Video

- Tutorial

品頁規(guī)格型號.png)